For information on introductions and applications please contact Deon Janse van Rensburg.

To reserve please use this calendarExternal link. Reservations are only possible for those who have been given an introduction.

Micro-XRF

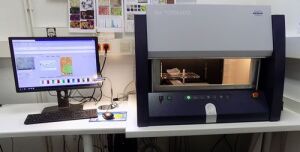

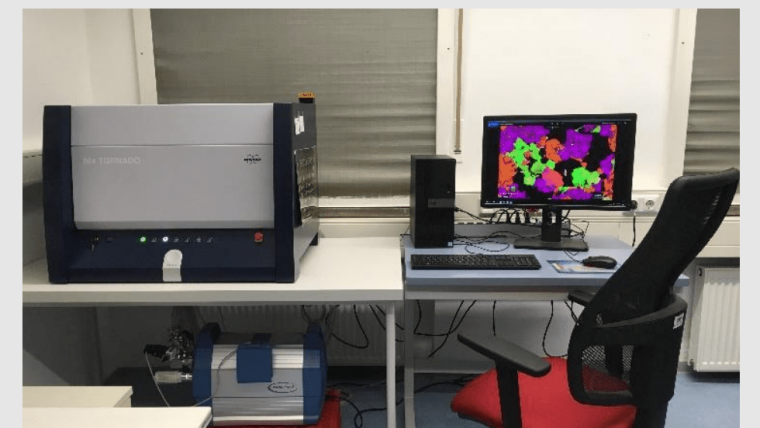

Image: C. HeubeckThe Chair of General and Historical Geology at IGW has been operating a combination of several desktop instruments for medium- and small-scale characterization of geological materials since June 2017. These include a Bruker Tornado M4 µ-XRF for mapping elements (not minerals!), a Keyence VHX-8000 digital microscope for 2-D and 3-D optical photography, and a Konica Minolta CM-700d spectrophotometer for field use.

We would like to thank the Thuringian Ministry of Economy, Science and Digital Society and the European Regional Development Fund (ERDF) for funding this project (CharAnGeoMat: Characterization and Analysis of Geological Materials at the Institute of Geosciences, Friedrich Schiller University Jena).

The µ-XRF has proven to be a workhorse in the working group and in the institute for the rapid characterization of the spatial 2-D distribution of elements. It is based on the narrow focusing of an X-ray beam to about 20µ, combined with fast spectroscopic analysis of the backscattered signal (from one or more elements) and the principle of rastering, i.e. fast systematic mapping of points. All data are digital. The instrument operates in point, line and area modes.

The specimen must be flat (sawn is sufficient; polishing improves the result only slightly), is placed horizontally on the stage, moved closely under the X-ray head and, by stage movement under the stationary X-ray head, is first photographed in detail and then scanned with X-rays. The computer stores the "composite spectrum" at each pixel (approx. 20*20µ) and deconvolves it into different intensities of several elements. These are reproduced as color intensities if desired.

We use the device for element and mineral identification and for pattern and structure recognition. The best results are usually achieved with medium to coarse grained or crystalline material. Tighter spacing of the points is useful up to about 18µ; below that the overlap becomes too high. Multiple overlap improves quantitative analysis, but not spatial resolution.

For more information see this poster pdf, 2 mb